Aluminum Casting and its role in sustainable manufacturing

Exploring the Vital Applications and Uses of Light Weight Aluminum Shop in Modern Production

Aluminum foundries play a vital duty in modern-day manufacturing, offering varied sectors with their one-of-a-kind residential or commercial properties. From vehicle components that enhance fuel effectiveness to aerospace structures that prioritize weight, aluminum's flexibility is obvious. Its applications encompass building and construction and consumer electronics, highlighting its resilience and energy efficiency. However, the developments in aluminum casting strategies and future trends require a closer evaluation, as they may redefine its impact on manufacturing.

The Role of Light Weight Aluminum Foundries in Automotive Manufacturing

As the automobile industry significantly focuses on lightweight products to boost fuel performance and efficiency, aluminum shops have actually become important factors to producing procedures. These factories specialize in generating elements that meet the rigorous demands of modern cars, such as engine blocks, transmission housings, and architectural elements. Light weight aluminum's desirable homes-- such as high strength-to-weight proportion, rust resistance, and excellent thermal conductivity-- make it an excellent option for automotive applications.

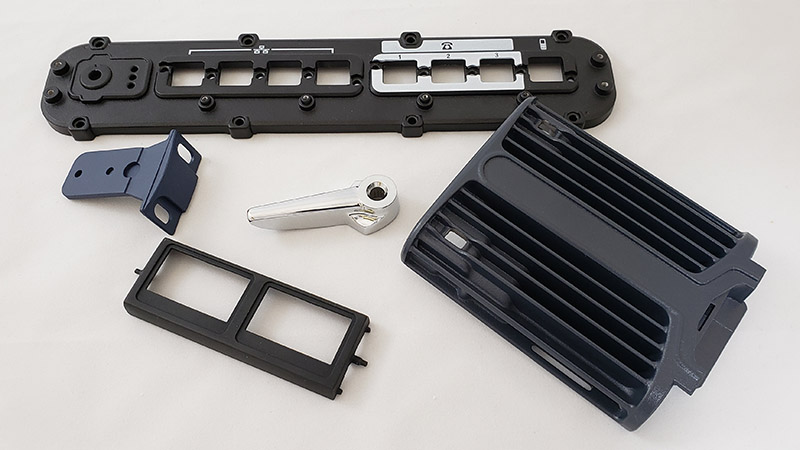

In addition, aluminum shops utilize innovative casting strategies, including die casting and sand spreading, to create detailed and resilient components. This capacity allows makers to maximize designs for performance while lessening weight. The use of aluminum likewise sustains sustainability objectives, as it is highly recyclable and decreases power intake in vehicles. By facilitating the combination of light weight aluminum right into auto design, factories play an essential duty in shaping the future of the auto industry, promoting effectiveness and advancement throughout the board.

Aerospace Applications: Lightweight Solutions for Trip

Light weight aluminum shops play a considerable duty in the aerospace sector, where the demand for lightweight materials is paramount for enhancing fuel performance and efficiency in airplane. The unique homes of aluminum, including its high strength-to-weight ratio and rust resistance, make it an optimal option for numerous aerospace components. These parts consist of architectural components, engine cases, and landing gear, which add to overall aircraft efficiency.

The usage of light weight aluminum alloys, specifically those created via innovative spreading methods, allows for the production of intricate layouts and intricate shapes while minimizing weight. Additionally, light weight aluminum's recyclability lines up with the aerospace market's sustainability goals, lowering ecological effect. With continual improvements in aluminum foundry modern technologies, makers can enhance production procedures, resulting in boosted effectiveness and reduced expenses. As the aerospace sector significantly prioritizes innovations that improve performance, light weight aluminum foundries will certainly remain indispensable to establishing lightweight services for modern trip.

Building and Building And Construction: Enhancing Structural Honesty

In the building and building and construction market, a substantial emphasis is put on improving architectural integrity via the usage of light weight aluminum. Understood for its high strength-to-weight proportion, aluminum supplies resilience without endangering on weight, which is vital in modern-day architectural layouts. Its resistance to corrosion additionally guarantees durability, making it an excellent material for different architectural components, including light beams, frames, and cladding.

Aluminum additionally facilitates ingenious design opportunities, permitting architects and engineers to create aesthetically pleasing frameworks while preserving security standards. The material's adaptability allows its application in both industrial and property tasks, from skyscrapers to bridges. Additionally, developments in light weight aluminum shop strategies have actually improved the precision of aluminum components, ensuring they satisfy strict building ordinance. Generally, the assimilation of light weight aluminum in building not just boosts architectural honesty yet also adds to lasting structure methods, provided its recyclability and energy-efficient production approaches.

Customer Electronic Devices: The Rise of Aluminum in Technology

In the domain of consumer electronic devices, light weight aluminum has actually gotten importance because of its lightweight design advantages and superior thermal conductivity. This change not just improves product portability but also boosts tool performance by efficiently dissipating heat. As technology remains to develop, the role of light weight aluminum in developing sleek and reliable gadgets is progressively significant.

Light-weight Style Advantages

As customer electronic devices evolve, the need for lightweight yet resilient products has actually surged, making light weight aluminum a progressively popular selection among manufacturers. Its reduced density enables the development of sleek gadgets that are easy to lug and utilize, considerably boosting portability. The strength-to-weight proportion of aluminum warranties that products can hold up against daily damage without jeopardizing efficiency. Additionally, the pliability of light weight aluminum allows suppliers to create complex forms and forms, better adding to cutting-edge looks and functionality. This lightweight feature additionally plays a vital duty in energy effectiveness, as lighter tools require less power to run. Because of this, light weight aluminum not just meets the progressing visual needs but likewise straightens with the modern focus on sustainability in customer electronic devices.

Thermal Conductivity Benefits

Thermal conductivity is a vital variable in the efficiency of consumer electronics, and aluminum master this domain name. Its high thermal conductivity permits efficient heat dissipation, which is vital for keeping optimum operating temperature levels in devices such as smartphones, laptops, and video gaming consoles. By assisting in quick warmth move far from delicate parts, aluminum helps prevent overheating, thus improving performance and prolonging device longevity. The lightweight nature of light weight aluminum complements its thermal properties, making it an excellent selection for mobile modern technology. As makers progressively prioritize performance and energy performance, light weight aluminum's function in thermal management ends up being much more significant, leading to its expanding fostering in contemporary electronic layouts. This fad underscores light weight aluminum's value in consumer electronic devices technology.

Marine Sector: Rust Resistance in Harsh Atmospheres

Rust resistance is a crucial variable in the aquatic market, where tools and structures are regularly revealed to extreme deep sea environments. Light weight aluminum, especially in its alloy kinds, uses significant benefits hereof. Its all-natural oxide layer offers a protective obstacle that prevents deterioration, making it excellent for vessels, docks, and other aquatic applications.

Marine-grade aluminum alloys, such as 5083 and 6061, are particularly created to hold up against the destructive impacts of deep sea and climatic problems. These alloys not just resist corrosion however also maintain architectural honesty and strength with time. Applications range from hulls and superstructures of ships to visit this website elements in overseas platforms.

The light-weight nature of light weight aluminum further boosts its suitability, making it possible for improved fuel performance and ease of handling - aluminum casting company. As the aquatic sector remains to concentrate on resilience and performance, light weight aluminum continues to be an important product selection for resisting corrosion popular aquatic settings

Advancements in Light Weight Aluminum Spreading Techniques

While traditional aluminum casting methods have served the sector well, recent advancements are changing the landscape of light weight aluminum production. Strategies such as 3D printing of mold and mildews and cores are acquiring grip, permitting quick prototyping and minimized preparations. This advancement enables producers to create complex geometries that were previously challenging to accomplish with traditional spreading techniques. Furthermore, improvements in die-casting innovation, including using high-pressure die-casting (HPDC), have improved the accuracy and surface area coating of cast aluminum components, leading to enhanced efficiency in numerous applications.

Furthermore, the fostering of financial investment spreading has actually enabled for greater layout liberty and minimized material waste. Casting Foundry. Technologies in alloy make-ups are likewise significant, as they boost mechanical properties and deterioration resistance. Generally, these developments not just enhance production processes yet likewise add to more sustainable methods within the aluminum foundry sector, making it versatile to the evolving needs of modern production

Future Patterns in Light Weight Aluminum Factory Manufacturing

The future of light weight aluminum foundry manufacturing is positioned for significant improvement via automation, improving performance and precision in producing procedures. Sustainable practices are progressively coming to be a priority, as factories look for to minimize their environmental effect while fulfilling growing regulatory demands. Furthermore, innovations in alloy development will allow the production of stronger, lighter materials tailored for diverse applications, driving advancement in the sector.

Automation in Shop Processes

Lasting Manufacturing Practices

An expanding focus on sustainable production methods is reshaping the future of light weight aluminum factory manufacturing. Market leaders are increasingly taking on energy-efficient innovations and reusing efforts to minimize waste and lower carbon footprints. The use of recycled light weight aluminum considerably decreases energy intake compared to key aluminum manufacturing, making it a favored choice for environmentally mindful manufacturers. Furthermore, innovative spreading techniques are being established to boost material efficiency and reduce discharges. Firms are also buying renewable resource resources, such as solar and wind, to power their operations sustainably. aluminum foundry. By integrating these techniques, the aluminum factory sector not only satisfies governing requirements however additionally reacts to customer demand for greener products, eventually leading the way for a much more lasting production landscape

Advanced Alloy Development

Developments in light weight aluminum alloy development i was reading this are set to play a considerable duty in the future of foundry production, particularly as sustainability and performance needs rise. The sector is significantly focusing on creating high-strength, lightweight alloys that can stand up to severe problems while minimizing environmental impact. Researchers are exploring innovative structures, such as aluminum-lithium and aluminum-scandium alloys, which guarantee boosted mechanical residential or commercial properties and minimized weight. Furthermore, the combination of sophisticated production methods, consisting of additive manufacturing and accuracy casting, enables more complex geometries and reduced product waste. As governing stress and customer preferences shift towards greener options, the development of recyclable and energy-efficient alloys will be important. The future landscape of aluminum shop manufacturing rests on these improvements in alloy innovation.

Often Asked Concerns

What Are the Environmental Influences of Light Weight Aluminum Factory Workflow?

Aluminum factory procedures can lead to significant ecological influences, including greenhouse gas emissions, power usage, and waste generation. Additionally, inappropriate monitoring of contaminants may cause soil and water contamination, influencing regional communities and communities.

Just How Does Aluminum Recycling Affect Shop Processes?

Light weight aluminum recycling boosts foundry procedures by offering an affordable raw material, lowering energy intake and discharges. This lasting method raises effectiveness, minimizes waste, and sustains the round economic climate, profiting both makers and the environment.

What Security Measures Are Carried Out in Aluminum Foundries?

Aluminum shops execute numerous safety procedures, consisting of personal safety equipment, appropriate air flow systems, regular security click for source training, fire avoidance methods, and equipment upkeep treatments to minimize hazards and guarantee a risk-free functioning environment for all workers.

Just How Do Foundries Ensure High Quality Control in Light Weight Aluminum Spreading?

Shops guarantee high quality control in light weight aluminum casting through extensive product examinations, precise temperature tracking, standard treatments, and normal screening of actors items. These measures help maintain consistency, decrease flaws, and fulfill sector requirements effectively.

What Are the Cost Elements in Aluminum Factory Production?

Price consider light weight aluminum shop manufacturing consist of resources rates, power intake, labor expenses, devices maintenance, and overhead costs. In addition, manufacturing quantity and intricacy of layouts substantially affect total production expenses and earnings.

As the vehicle market progressively prioritizes lightweight products to improve fuel efficiency and performance, light weight aluminum shops have come to be essential contributors to manufacturing processes. Light weight aluminum factories play a considerable function in the aerospace sector, where the need for light-weight products is vital for improving fuel performance and performance in aircraft. In addition, improvements in aluminum shop methods have boosted the precision of light weight aluminum elements, ensuring they satisfy strict structure codes. While standard aluminum spreading methods have actually served the sector well, recent developments are changing the landscape of aluminum production. The use of recycled aluminum significantly lowers power consumption contrasted to primary light weight aluminum manufacturing, making it a preferred selection for environmentally mindful manufacturers.